In today’s globalised world, the global-shrinkage caused by the technological revolution has enabled the people of the world to become increasingly homogenous; in terms of Culture, Beliefs and Knowledge. “Variety is the spice of life”, as a creative individual and an enthusiast over alternatives myself, I value the ability to create and innovate. That is why when I learnt about the “World’s first Smartphone 3D Printer”, I marvelled in awe.

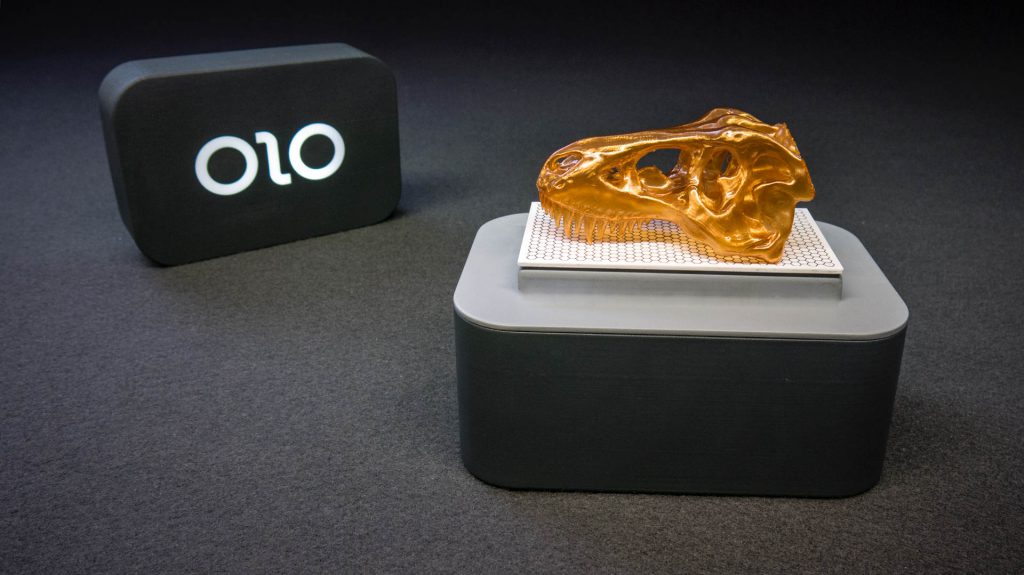

It’s impressive because you are hearing from someone who had the pre-notion that 3D printers are always these industrial-sized machinery stashed in huge laboratories, monopolised by highly-secretive government operatives. OLO 3D Inc has invented the first ever Smartphone 3D Printer, OLO, outgrowing (not literally) the manufacturing industry and allowing us to catch a glimpse of the future of manufacturing.

However in my opinion, for an accessory to be personally-fulfilling, it must pass 3 vital benchmarks: Design, Functionality and Versatility. Furthermore, for a price tag under US$100, cost factors are definitely not a problem.

1. Design

For me, a product’s design is paramount to the efficiency and applicability of its functions. I’d love to have a 3D printer that is lightweight, compact and simple to use. In contrast, I wouldn’t use a 3D printer if it was too space-consuming and extraneous to the aesthetics of my home or my office. Since the OLO printer is only 780 grams and measures at 172 x 115 x 148 mm, it proves to be a convenient tool that blends in with my personal space, being as big as the box that my smartphone came in.

Furthermore, I have to admit, the printer’s futuristic block-like shape and the flushed-finish on its rounded edges looks pretty dope. Even if I let it collect dust on my table, I think it would pass off as a pretty dapper tissue box. Ultimately, it is always fulfilling to know that I am now able to create something with just my smartphone.

2. Functionality

The 3D printer prints at a proficient speed in relation to its compact size. OLO claims that with an iPhone 6, it can construct 1cm in approximately 46 minutes and 1 inch in approximately 1 hour 55 minutes. Since my smartphone has grown to become an extension of myself, the 3D printer should have no problems assimilating into my lifestyle and as an extension of my phone, given that it operates on an app that is compatible with Apple iOS, Android OS and Windows phones (extension-ception).

How is it possible to print from our smartphones? After pouring the special resin substance into the printer, the z-axis of the OLO 3D printer raises progressively as each layer is formed. The white light from our smartphones cure these special resins which OLO calls “Daylight Resins”.

Sadly, the OLO 3D printer only runs on 4 standard AA batteries and cannot be plugged into a power source. Meaning that you’ll always have to buy new batteries or constantly re-charge rechargeable ones. In addition, as its compact size boosts portability, it degrades product variety. It would be impossible to print something big, such as a new sole for the shoe you broke last week.

3. Versatility

Just like how the mobile phone has grown from only making calls to now being able to double up as calculators, compasses, televisions, maps and even as door keys, the OLO 3D printer has to be versatile in its uses. Can the OLO 3D printer use other printing materials? We’ve seen 3D printers using organic ink to print organs in the healthcare industry, and edible ink to print garnishes in the food industry.

Disappointingly, the OLO 3D printer can only print with OLO’s own brand of resins which range from being elastic to flexible to hard.However, who is to say that it ends there? Furthermore, OLO has not begun mass-producing its products to the commercial market. In fact, its Kickstarter campaign is backed by 15,224 contributors and has crowdfunded $2,183,113 as of the 16th of April 2016. To have your questions answered, click here to go to OLO’s FAQ homepage.

Needless to say, the range of products one can create are endless—chess pieces, rings, smartphone cases…

In a nutshell, I would love to start designing and manufacturing my own customised creations, such as smartphone cases, name card holders (as shown below) and even the name cards themselves. That said, having a domestic 3D printer within arm’s reach can revolutionise how we brand ourselves in the homogenous society we live in.

From a broader perspective, we’d ask, “What about the future of manufacturing?” Surely Fordism and mass-production practices will be eroded by the more customisable, cost-efficient and intimate experience of personal manufacturing provided by these domestic 3D printers.

Further down the road, we’ll see a change in the way we commerce and market our products and ourselves. The potential development of biodegradable and reusable resins by these 3D printer companies can also help to make manufacturing more environmentally friendly and tailor our inventions and products to be more environmentally and communally enabling.

I’m excited for what comes next from this point onwards, and as an individual with the ability to create and impact the world we live in, you should be too.

Also Read: It’s A Great Time To Be A Programmer In Singapore Now