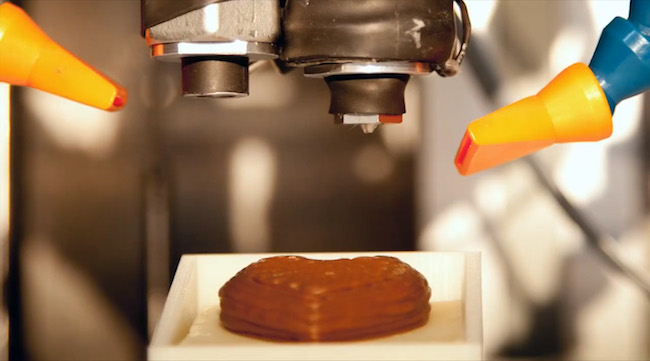

The future is here—and has made its way into almost every industry in our globe. 3D Printing has even found its way into our healthcare services.

The term 3D Printing explains a manufacturing approach that builds objects by adding layers to form them. It is also described as additive manufacturing and is also known as rapid prototyping. 3D Printing has been greeted as a disruptive technology that will bring changes to the manufacturing industry. It is used in defense, aerospace, design, and art and is also becoming a subject of interest in surgery.

3D Printing is used by the local Queens dentist, Dr. Tony Le, to produce drill guides for dental implants, orthodontics, and surgery, physical models for prosthodontics.

Below, we’ll discuss the details of 3D Printing and how it has become a staple in the dentistry industry.

3D Printing Technology

From a mechanical perspective, 3D printers are robotic devices that are very simple. Without a Design software that is aided by computers, these devices would be nothing as they allow objects to be designed in a virtual environment. CAD is standard in engineering, industrial design, and manufacturing environments. It is common in dentistry too, and is becoming a common feature of dental surgery.

Computer technology development and software application are part of technology change that has taken 3D to where it currently is. 3D Printing derives its value by being able to create objects to print. CAD software makes objects from scratch.

It helps dentistry because it gives ready access to volumetric data in cone-beam computed tomography data, computed tomography, and laboratory optical surface scan data.

Dentistry has familiarized with materials designed to work with CAD-CAM to substitute for traditional precious metal casting alloys, which have faced an increase in prices over the past years.

3D Printing is rapidly growing in dentistry because 3D printers and materials specifically for dentists are already being manufactured. It is projected that the sale of 3D printing systems to dental labs will double up in a few years to come, and dental needs production to increase.

Capabilities of 3D Printing In Dentistry

The following applications use 3D in dentistry:

Medical modeling

It is one of the earliest applications of 3D Printing in surgery. CBCT has become mainstream in dentistry, and it has changed the diagnosis and treatment in implant dentistry.

3D Printing can handle volumetric image data and can make detailed replicas of the patient’s jaw. It has led to new procedures like drilling and cutting using 3D printers.

Drilling and cutting guides

The use of drill guides in implant dentistry is becoming common. The use of cutting guides and drill guides allow a virtual 3D plan created on-screen in software to be transferred to the operative site.

Crown cutting and partial dentures frameworks

During laboratory scanners or intraoral optical scanners, making a specific virtual model of a prepared implant, tooth, and the dental arch is easy.

Dental models for restorative dentistry

The use of intraoral scanners means there is a need for a physical model of the scanned jaw. However, today it is unnecessary to print a master model because the 3D printed master model could be used for the conventional aspect of the fabrication of restoration, like adding a veneering material.

In addition to that patient model, data can be archived digitally and printed only when needed easing storage requirements.

Digital orthodontics

Orthodontics needs treatment to be planned and appliances to be created. The digital workflow requires optical scanning to bend wires robotically in the laboratory or capture patient data using CBCT.

The patient’s teeth are realigned digitally using the Invisalign system to produce a series of models to manufacture the aligners.

Benefits of 3D Printing in Dentistry

Dentistry relied on laboratories to produce bridges, crowns, and other implants for many years. The following are benefits of 3D Printing:

- Dentists save money. Improving dental laboratories is an essential cost for any dental practice, but when 3D Printing gets into dentistry, it will help save a lot of money.

- Patients save money because it eliminates the high cost of having a laboratory reflects into each patient’s bill. Therefore, with 3D Printing, the dentist can save a lot of money while passing it over to the patients.

- Dental and orthopedic services are more accurate and faster. Making models manually takes time, and 3D Printing will allow multiple appliances printed previously. You can be much more accurate when converting 3D images into actual objects. This will benefit both the patients and the dentists.

Final Thoughts

3D resonates well with dentistry because of its advances in modeling technologies, 3D imaging, and intraoral scanning. Therefore, the use of CAM-CAD technologies in dentistry will become of great importance.

Adopting 3D Printing in dentistry will improve dental practices and make them more efficient.