In the age where the internet allows you to customise and cater content specifically to you, the interest in customised things has risen as well.

We recently wrote about ChubbeeCloud, a service where you can customise your own marshmallows, as well as Xalf, where you can buy bespoke shoes. There is even OLFAC3, where you can book sessions to customise your own unique scent.

The same goes for t-shirts as well.

Every company wants t-shirts and jackets emblazoned with their branding. There’ll be events or competitions, or just individuals who want their own designs on a shirt.

Mutant Dreams is one such startup catering to the demands of customisation.

Their prints can be transferred among other things, onto t-shirts, bags, lanyards, umbrellas, cardboard and paper.

According to them, their prints are more vivid and durable than the direct-to-garment approach, as well as much cheaper than silk screening designs onto a garment.

This is why they think that they can stay ahead and stay relevant only by printing stickers.

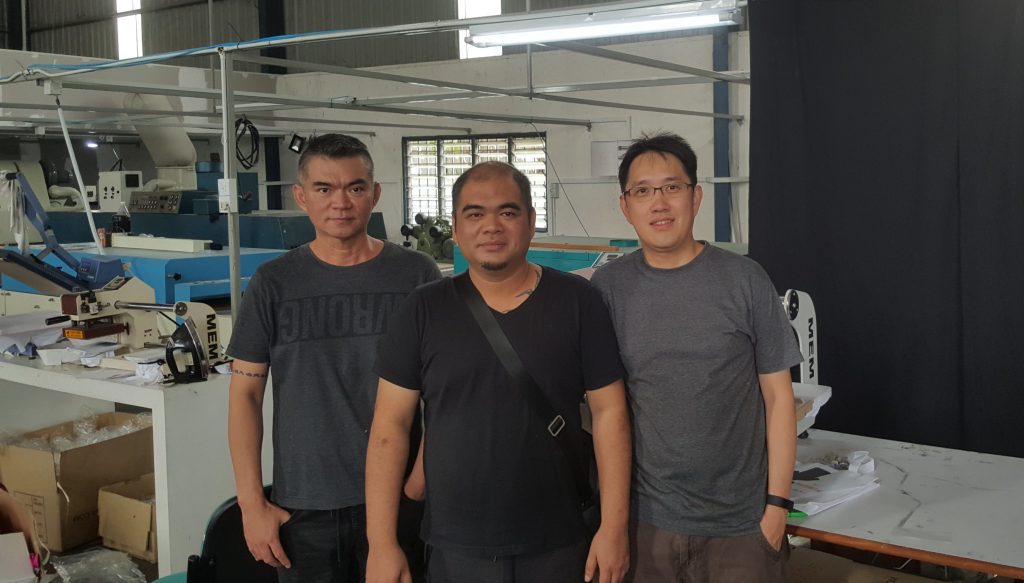

Founders Ong Kok Sun and Freddie Koh have over 2 decades worth of experience in the textile industry between them.

Backed by a t-shirt wholesaler and startup MD Textile, they set out to develop their own unique technology.

Back in December last year, they discovered that they were actually able to make heat transfer stickers without the white borders, almost by chance.

Ong told us, “We were just messing around with ink and raw material formulations, when the first product, V1, was conceived.”

“It was just good luck that when we put the idea to a test using our own resources, we found that it’s commercially viable.”

It may sound unremarkable to us outside the industry, but the Mutant Dreams team told us otherwise.

“Borderless heat transfer stickers are the holy grail of textile printing technology. It opened up the possibility of printing on products like bags, lanyards, umbrellas, and notebooks. Current heat transfer stickers can only work on t-shirts.”

– Ong, co-founder of Mutant Dreams.

According to Ong, “Traditional printing processes have many limitations, but customer expectations keep on increasing.”

“The other methods typically used to achieve this borderless print is the Direct-to-Garment Inkjet print, which has limitations in terms of print quality, speed and cost.”

“Think of it this way. We just reinvented the car. What if we can just be the Uber or Airbnb for heat transfer prints?”

The Mutant Dreams team promises that all orders are processed and manufactured within 48 hours, thanks to their tech development.

But getting there wasn’t a breeze.

“The first version, V1 couldn’t pass current industrial quality standards in terms of durability. The prints were impeccable and of high resolution, but cracked when stretched and the colour ran when washed.”

“We had to take the risk and procure expensive machinery, which we didn’t even know would work. We had to modify the machinery, make many ink and glue formulations and camp in the 24-hour dobi to do wash tests in the middle of the night.”

For six months, the team was fully occupied with these and numerous other problems in order to develop what they named the HD Printing method.

The latest version of their stickers can withstand 50 cycles in the washing machine with only minimal discolouration, and what the team calls a “soft hand feel”.

With all the work they’ve put in, they’re understandably proud of their product.

“HD Prints is simply superior compared to traditional printing methods. To put it simply, it is better, faster and cheaper than the alternatives. It is also scalable, easy to distribute and can be stored.”

The small team of 9 is still in a continuous R&D mode to further improve their produce on top of running their everyday routine of printing client commissions.

In total, about RM1 million has already been pumped into their business.

This cost includes machinery, raw materials and research funds into their method.

The team is very optimistic, and are already turning a profit based on normal accounting practices. This is if you only count cost of wages, raw materials and day to day expenses.

When you factor in their extensive R&D process and machinery, Ong admitted that it will be some time before the team can see profit.

“When will we recover everything? We don’t know yet. We are still investing to address a new problem: How to scale and export.”

Paving a new way isn’t easy.

Beside their other obstacles mentioned earlier, Ong mentioned that he sometimes encounters “disbelief”.

“They have never seen a product like this, are afraid to try it or are just simply in denial, preferring to use methods they are more comfortable with.”

To combat these difficulties, they’ve been running an aggressive marketing campaign to get clients on board, providing free samples as well as steep discounts for first-time customers.

They’re keen to bring the results of their development overseas. Since they believe their technology is one of a kind, they see a huge potential for cross-border business.

Feature Image Credit: Mutant Dreams