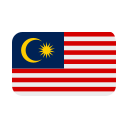

When Roland Tee retired as an auditor in 2009, he realised from reading newspapers that there needed to be a more environmentally friendly way to dispose of our country’s waste.

“The more I read, the more I realised that there is so much news related to waste management issues, weaknesses and conundrums, which aren’t met with effective solutions,” he said.

“Technologies that have been constructed are often high in cost in terms of investment, operating expenses, and maintenance. They frequently break down and often end up left idle and not operated.”

So, he met up with a few friends who were university professors to find out if there was a way to burn garbage without using diesel.

That became his baseline to create a machine that virtually left no carbon footprint behind.

“I was in my early 60s in 2010 when I came up with the first prototype. I went through numerous trial and errors, part by part, section by section of the ASHER before putting all the pieces together as a workable unit,” Roland shared.

Putting The Invention To Use

The ASHER is essentially a tiny trash incinerator that’s 6 metres tall and can reduce most solid waste materials (except glass and metals) into ash.

It uses built-in solar panels to continuously operate once just a small fire is lit in it, which means it can burn nonstop and is self-sustainable, as long as trash is being fed to it.

The longer the machine is in continuous operation, the higher its internal temperature grows.

In it is also a filtration system that filters out any toxic compounds and gases from the burning, and what leaves the machine is claimed to simply be lukewarm steam.

To make sure his invention was safe and environmentally friendly, Roland put it through extensive tests.

Some of the laboratory agencies he went to were SGS and MYCO2, which are inspection and certification companies for industrial and chemical products.

“The results proved that the ASHER could comply with both compliance and environmental aspects. For example, the discharge coming out from the ASHER is substantiated and backed up by the tests that I have conducted,” he said.

It cost Roland over RM3 million to create the current machine being used today. It’s also gone through 3 generations since its prototype in 2010.

Initially promoting his invention through a small network of friends, Roland eventually approached Pamarai Sdn Bhd for a potential partnership to expand and grow the ASHER.

“I decided to form a long term working relationship with Pamarai as they’re experienced in the waste industry, making them a very suitable partner to help me to get the ASHER out there more effectively,” he said.

Pamarai’s executive director Pang Swee Lei and chairman Datuk Mohamed Razeek were impressed by the invention too.

“The moment we had a deep understanding of its simple principles combined with applied technologies, we realised it is destined to be a game-changer,” they said.

Now, the ASHER is exclusively distributed and registered under Pamarai and costs around half a million ringgit per unit.

As of today, 75 units of it have been deployed to 13 countries including Singapore, China, India, Nigeria, Australia, and the Philippines, to name a few.

Turning Waste Into New Revenue Streams

Because the machine is so small, we were reminded of community recycle bins placed around neighbourhoods for the public to dump old clothes, electronics and other recyclables.

But the team told us that this is not the case for the ASHER. Although the machine is safe and easy to use, it can still be a hazard if handled improperly.

“Ideally, the ASHER should be manned and operated by a trained and designated personnel, whilst the accessibility to the public shall be limited until the point of dropping off at the temporary storage containers, before loading into the ASHER,” said Datuk Mohamed Razeek.

However, there are currently two ASHERs that are accessible to the Malaysian public.

“One is in Taman Sejahtera Rakyat Sg. Toh Pawang, Kedah which is being operated, maintained and managed by the kampung folks themselves,” Pang said.

“The other is at the recycling centre in Seksyen U2 TTDI Jaya, Shah Alam which is owned by the local council, Majlis Bandaraya Shah Alam.”

Apart from these publicly accessible ones, Pang told us that most of the ASHER units are used by private companies to manage their own waste within their premises.

Ash from the machine can be repurposed as soil conditioner. By adding a simple mixture of soils and animal dung, it can be suitably categorised as fertiliser.

“Compared with the lowest grade and cheapest fertiliser, those produced from the ASHER can be cheaper by up to 40%,” said Pang.

“The ASHER’s users are reprocessing the ash and selling it, while reusing their waste within their own premise for general landscaping.”

A Small Machine Aiming To Solve A Global Problem

In the Philippines, the local municipal in Marikina set up an incentive programme where residents would be rewarded by bringing in waste generated from their homes or those cleaned up off the streets to the ASHER.

Thus, it was able to reduce the cost of waste collection by 75% per tonne.

Its resulting ash is mixed with sawdust and sold as fertiliser to farmers, allowing a new income stream for the district.

However, the team told us that some materials burnt in the machine like diapers and plastics can’t be turned into fertiliser.

“It can still be used for multiple purposes such as general landscaping and conversion into building materials.”

“A temple in India turns ash into sand bricks, which are used to repair the temple, build more benches, and create pavements around the grounds,” Datuk Mohamed Razeek said.

Government agencies have expressed interest in collaborating with Pamarai to market and introduce the ASHER overseas through a government-to-government programme.

They are currently in the final stage to obtain a MyHijau certification mark for the ASHER.

Editor’s Update (2/10/2020): The ASHER has since received its MyHijau certification mark as of September 24.

It’s a green label given out by the Malaysian Green Technology Corporation, an agency under the purview of the Ministry of Environment.

“The ASHER ultimately can help the government to save a large amount of cost spent in waste management annually,” he said.

“Evolving from there, the government can utilise the ability of the ASHER to provide service to other countries to assist in waste disposal issue, especially the issue of illegal and non-recyclable plastics.”

Featured Image Credit: Roland Tee, inventor of the ASHER